Manufacturing Reshoring 2025: Indianapolis Companies Navigate SBA Loans & Government Incentives for Supply Chain Independence

Reshoring—the strategic move to bring manufacturing back to U.S. soil—and nearshoring—relocating operations to nearby countries such as Mexico and Canada—have surged in priority for Indianapolis manufacturers in 2025. This article explores why local companies are leading this resurgence, the capital financing needs they face, and how they are leveraging SBA loans and a variety of government incentives to regain supply chain independence amid geopolitical risk and global disruptions.

- Manufacturing Reshoring 2025: Indianapolis Companies Navigate SBA Loans & Government Incentives for Supply Chain Independence

- Table of Contents

- Key Drivers of Reshoring and Nearshoring in 2025

- The Capital Challenge: Financing Reshoring & Nearshoring

- SBA Loans: The Backbone of Reshoring Finance

- Federal and Indiana State Incentives for Relocating Manufacturers

- Case Studies: Indianapolis Manufacturers Reshoring with Success

- Financing Automation: Maximizing the ROI of Domestic Production

- Navigating Workforce, Supply Chain, and Lead Time Challenges

- Actionable Financing Insights for Manufacturers Considering Reshoring/Nearshoring

- Indianapolis Capital & Support Resources

- Conclusion: The Path Forward for Indianapolis Manufacturers in 2025

Table of Contents

- Key Drivers of Reshoring and Nearshoring in 2025

- The Capital Challenge: Financing Reshoring & Nearshoring

- SBA Loans: The Backbone of Reshoring Finance

- Federal and Indiana State Incentives for Relocating Manufacturers

- Case Studies: Indianapolis Manufacturers Reshoring with Success

- Financing Automation: Maximizing the ROI of Domestic Production

- Navigating Workforce, Supply Chain, and Lead Time Challenges

- Actionable Financing Insights for 2025

- Indianapolis Capital & Support Resources

Key Drivers of Reshoring and Nearshoring in 2025

- Global Disruption Risk: Red Sea attacks, persistent tariffs on Chinese goods, and unpredictable international freight rates have exposed the vulnerability of extended supply chains.

- Policy & Tariffs: The U.S. continues to weigh new tariffs and trade enforcement against countries outside North America, encouraging a regional “fortress supply chain.”

- Customer Demands: Speed-to-market, ‘Made in USA’ preferences, and ESG considerations are increasingly prioritized by buyers.

- Technological Advancements: Robotics, automation, and digital manufacturing enable cost-competitive production in the U.S. and across the USMCA corridor.

- Workforce Realignment: Initiatives in Indianapolis to upskill workers and reintegrate talent into advanced manufacturing sectors.

The Capital Challenge: Financing Reshoring & Nearshoring

Relocating or expanding manufacturing is capital intensive: new facilities, cutting-edge equipment, robotics, working capital for long lead times, and higher skilled labor. Indianapolis businesses must carefully structure financing that aligns to high upfront costs and the long ramp-up phase typical of domestic manufacturing investments.

- Equipment & Automation: Advanced machinery and robotics can require investments ranging from $250,000 to over $20 million per factory.

- Facility Development: Retrofitting or building to modern safety and energy efficiency standards.

- Working Capital: Covering the gap for inventory, receivables, and staffing as operations scale.

- Training & Labor: Workforce development now often includes automation, robotics, and digital manufacturing skills.

This is where government support—particularly SBA loans and incentive programs—plays a critical role.

Need capital? GHC Funding offers flexible funding solutions to support your business growth or real estate projects. Discover fast, reliable financing options today!

⚡ Key Flexible Funding Options:

GHC Funding everages financing types that prioritize asset value and cash flow over lengthy financial history checks:

DSCR Rental Loan

- No tax returns required

- Qualify using rental income (DSCR-based)

- Fast closings ~3–4 weeks

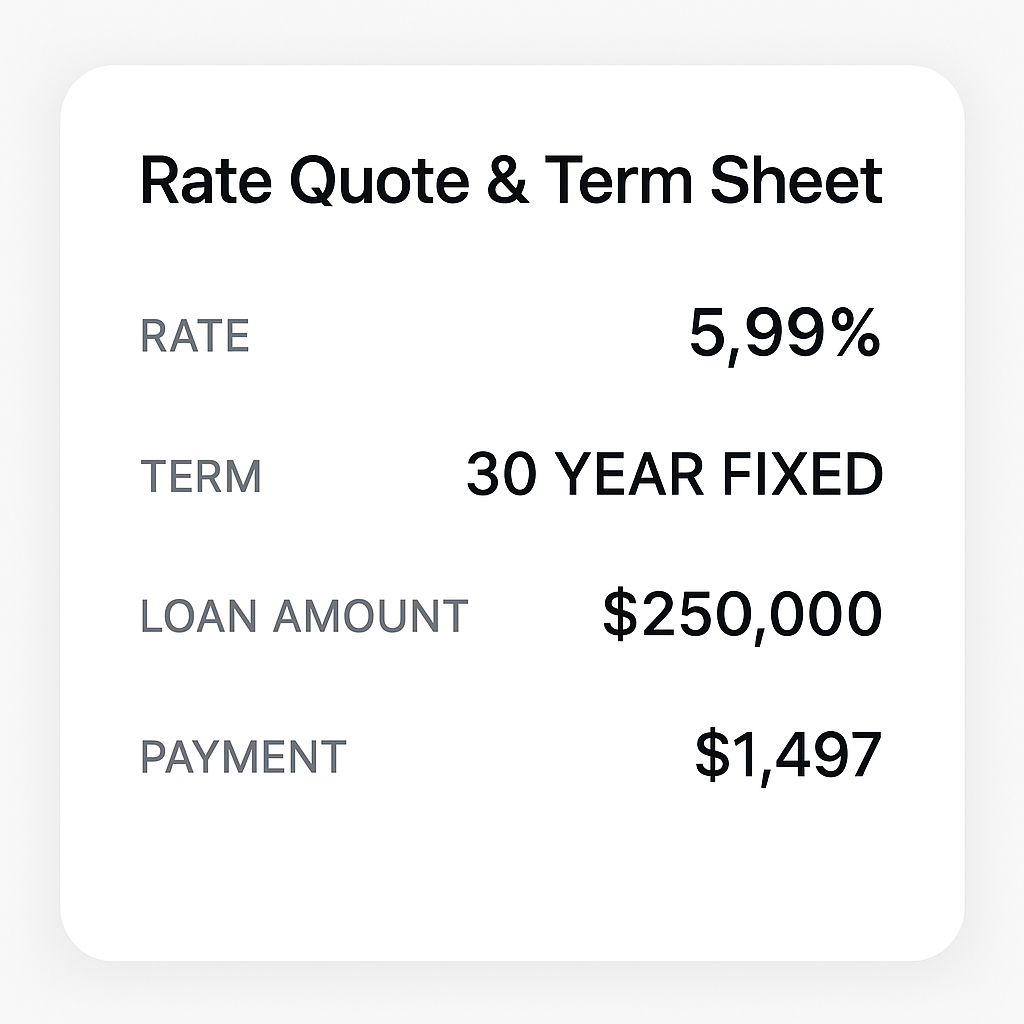

SBA 7(a) Loan

- Lower down payments vs banks

- Long amortization improves cash flow

- Good if your business occupies 51%+

Bridge Loan

- Close quickly — move on opportunities

- Flexible underwriting

- Great for value-add or transitional assets

SBA 504 Loan

- Low fixed rates through CDC portion

- Great for construction, expansion, fixed assets

- Often lower down payment than bank loans

🌐 Learn More

For details on GHC Funding's specific products and to start an application, please visit our homepage:

SBA Loans: The Backbone of Reshoring Finance

The U.S. Small Business Administration (SBA) administers highly attractive financing programs for manufacturers looking to reshore or nearshore operations in 2025:

- 7(a) Loan Program: Offers up to $5 million in flexible financing for equipment, property acquisition, and working capital. Many Indianapolis manufacturers use this for initial build-outs and automation system purchases.

- 504 Loan Program: Specifically designed for real estate and major equipment investments (up to $16.5 million project size). Low, fixed-rate financing is ideal for large automation and plant upgrades.

- SBA Express: Rapid approvals on loans up to $500,000—supporting fast-moving reshoring projects or supplier pivots.

2025 Updates: SBA programs have increased their guarantees and streamlined application requirements for reshoring-related projects. Special provisions for minority-owned, rural, and advanced manufacturing businesses mean more Indy companies qualify.

Federal and Indiana State Incentives for Relocating Manufacturers

- CHIPS and Science Act Incentives (2025): New funding available for semiconductor, electronics, and strategic suppliers returning to U.S. soil.

- Advanced Manufacturing Tax Credits: Enhanced depreciation, bonus depreciation, and R&D credits are available for Indiana-based manufacturers investing in new technology or clean manufacturing processes.

- Indiana Economic Development Corporation (IEDC) Incentives: IEDC provides tax credits, training grants, and site development funding for companies reshoring jobs to Indianapolis or establishing regional USMCA supply chains.

- Workforce Training Grants: State and federal funds supporting upskilling and talent pipeline programs.

- USMCA Certification Assistance: Guidance and subsidies for manufacturers and suppliers seeking to certify goods as North American origin to avoid tariffs.

Case Studies: Indianapolis Manufacturers Reshoring with Success

Case Study 1: IndyTool Components – Bringing Machining Back from Asia

Background: For over a decade, IndyTool Components sourced precision parts from suppliers in Thailand and China. In 2024-2025, rising tariffs (an additional 10% under new U.S. regulations) and Red Sea shipping delays (with transits increasing costs by 30%) threatened margins and customer delivery commitments.

Solution: Using a combination of an SBA 504 loan and an Indiana State equipment grant, IndyTool invested .5M in a new robotics-enhanced machining facility in Park Fletcher. They integrated lights-out automation, slashing labor requirements by 40% while improving quality. Key capital needs covered included:

- $4.2M – Automation equipment (5-axis CNC, robotic arms, conveyor systems)

- $1.8M – Facility upgrades and energy efficiency improvements

- $500K – Workforce recruitment and robotics training, supported by state grants

Outcomes (2025):

- 85% reduction in critical supply chain disruptions

- 7% improvement in gross margins

- Ability to guarantee 2-week delivery windows for Midwest OEM customers

Case Study 2: Circle City Plastics – USMCA Nearshoring to Mexico

Challenge: 2023-2024 saw resin shortages and multi-month delays from Asia. Circle City Plastics sought to partner with a new injection molding supplier in Monterrey, Mexico, capitalizing on the streamlined USMCA trade regime.

Financing Approach: Leveraging an SBA 7(a) loan and an Indiana Export-Import Bank working capital line, Circle City financed the shift—including tooling transfer, new Mexican supplier audits, and expanded logistics operations connecting Indiana and Monterrey.

Result:

- Decreased lead times from 90 days (Asia) to 19 days (Mexico)

- Avoided $800,000 in annual tariff liability

- Protected Midwest customers from global supply chain shocks

Financing Automation: Maximizing the ROI of Domestic Production

Modern U.S. and North American manufacturing relies on world-class automation and robotics to offset higher wage costs. However, the upfront investment challenge remains formidable.

- Cost of Robotics: Indianapolis manufacturers report average payback periods of 2.5-4 years for advanced robotics—down from 5+ years a decade ago, thanks to higher U.S. labor costs and improved robotic reliability.

- Equipment Financing Partnerships: Many companies blend SBA loans, vendor equipment financing, and private lenders to fund upgrades—spreading cash flow impact and enabling faster facility commissioning.

- Tech Investment ROI: Automation boosts throughput, eliminates human error, and facilitates ‘smart factory’ predictive analytics—key to maintaining global competitiveness.

Navigating Workforce, Supply Chain, and Lead Time Challenges

- Long Lead Times: Facility construction and machine delivery now average 15-24 months, making working capital lines (including SBA and alternative lenders) crucial for bridging periods of cash burn.

- Skilled Labor: Indianapolis companies increasingly tap local technical colleges and state-supported apprenticeship programs to address shortages in automation and systems integration expertise.

- Supply Chain Redundancy: Manufacturers are investing not only in single-site reshoring, but also in regional supplier diversification to reduce risk.

Actionable Financing Insights for Manufacturers Considering Reshoring/Nearshoring

- Assess Full Cost of Global Disruption: Quantify impacts of shipping delays, tariff escalation, and customer attrition. Let these real costs drive your ROI calculations for reshoring.

- Map Capital Needs Early: Build a funding stack (SBA, state, private lenders, lease financing) that aligns to project phases—facility, equipment, working capital, and workforce.

- Leverage Local Incentives: Contact IEDC and local Commerce departments to maximize grants, tax breaks, and workforce subsidies.

- Start the SBA Process Sooner: Gather business plans, projections, and supplier contracts early. In 2025, streamlined digital underwriting can deliver pre-approvals in weeks, but competitive funds are quickly allocated.

- Partner with Specialist Financiers: Work with lenders and advisors experienced in manufacturing, automation, and international supply chain transitions.

Indianapolis Capital & Support Resources

- Indiana Economic Development Corporation (IEDC): www.iedc.in.gov

- SBA Indiana District Office: www.sba.gov/offices/district/in/indianapolis

- Indiana Manufacturers Association: www.indianamfg.com

- Conexus Indiana Advanced Manufacturing Workforce Program: www.conexusindiana.com

- SCORE Indianapolis: Free business advice; www.score.org/indianapolis

Conclusion: The Path Forward for Indianapolis Manufacturers in 2025

Indianapolis stands at the forefront of America’s reshoring and nearshoring renaissance. As global events make traditional supply chains less reliable and more expensive, the combination of SBA loans, government incentives, and a robust ecosystem of public-private support allows Midwest manufacturers to capitalize on this pivotal moment. With disciplined planning and a strategic approach to automation and working capital, local manufacturers are not just navigating disruption—they are seizing a generational opportunity to rebuild U.S. industrial strength.

Get a No Obligation Quote Today.

Use these trusted resources to grow and manage your small business—then connect with GHC Funding

to explore financing options tailored to your needs.

GHC Funding helps entrepreneurs secure working capital, equipment financing, real estate loans,

and more—start your funding conversation today.

Helpful Small Business Resources